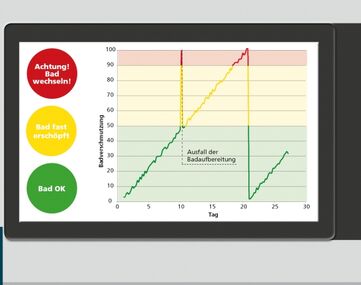

Compliance with defined standards for the cleanliness of a specific part is a required characteristic of the workpiece to be cleaned. In order to guarantee the functionality of the part, obligatory technical purity standards are thus defined. At the same time, the defined level of cleanliness for the workpiece is important for the subsequent processing step in order to achieve a smooth production flow. The BvL Libelle system maintains and monitors the bath quality and the cleaning performance. Sensors measure and monitor various different factors that influence the bath quality and document the processing parameters.

- Libelle Fluid Control - monitors the condition of the bath

- Libelle Oil Control - measures the oil content in the medium

- Libelle Cleaner Control - measures the cleaning agent concentration

- Libelle Oil Control Solo - measures the film contamination on the component surface

- Libelle Data Control - documents process parameters

- inspects and ensures the cleaning results

- minimizes the number of rejected parts

- documents the cleaning process

- optimizes the service life of the bath