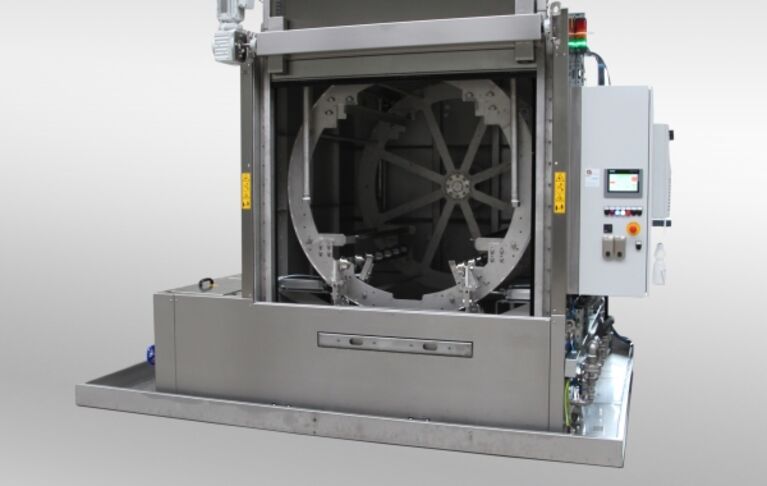

| Cleaning system: | spray cleaning with flat spray nozzles |

| Operating principle: | rotating, revolving wheel system with vertical nozzle frame which swivels in front of the face sides |

| Number of tanks: | 1-2 |

| Loading: | front loading through a roller guided holding fixture |

| Housing: | stainless steel |

| Tank insulation: | stainless steel |

| Control and operation: | Siemens Simatic with Siemens touch panel |

| Bath monitoring: | Libelle Fluid Control |

Intelligent cleaning with BvL apps and digital networking! Transparent process information for predictive system diagnostics and maintenance: efficient and automatic.

- for bulky, heavy workpieces and complex geometric shapes

- for use with Euro box pallets (and others)

- for large quantities

- for light to medium soiling

Technology in detail

Cleaning technology

Cleaning technology

- holding fixture revolves or swivels around the horizontal axis

- all-round cleaning through special nozzle frame

- a separate nozzle frame for each tank reduces mixing

- nozzles and nozzle frames can be adapted to the workpiece

- adaptation of useful dimensions, loads and pump capacities possible

Processing steps

Processing steps

The processing steps are carried out in a chamber:

- spray washing

- spray rinsing (for two-tank system)

- circulating air drying (optional)

Options and supplements

Options and supplements

- drying sytems

- handling systems: loading carriage, cross movement table,bridge loader and automation

- increased pump capacity

- bath maintenance options

- process reliability: Libelle Cleaner Control, Libelle Oil Control, Libelle Data Control, remote diagnosis

- cascade guiding

- floor drip tray

- other system components