Hardening shops

Cleaning solutions for heat treatment processes

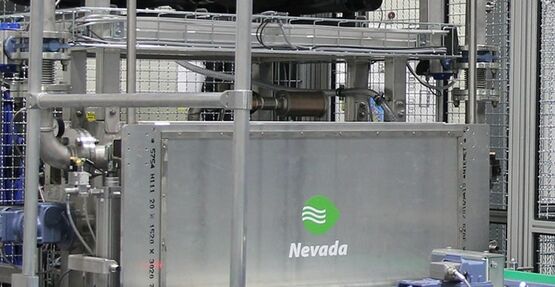

Heat treatment processes require residue-free, stainless parts because any residues can cause flawed processing results. The production of an even layer during subsequent processing can only occur if the components are exceptionally clean. We developed the NiagaraVE spray/flood system for these special applications. It stands out due to its optimal cleaning results and reliability.

The integrated vacuum drying system ensures that the workpieces are absolutely dry – which is often an essential requirement in hardening shops. This processing step is included in the design and implementation of the system if required for your parts.

- Suitable for heavy parts or lots of parts with a high total weight

- Residue-free, stainess parts

- Temporary corrosion protection can be applied

- Optimal cleaning despite a high batch density